We’ve worked in the playground industry for years now and through that time we’ve collected lots of information about the dos and don’ts of playground surfacing.

There are a number of mistakes we’ve seen people make when choosing and installing a surface for their playground. So, we’ve compiled a list of the 11 most common mistakes to share with you, along with some things you can look out for, so you don’t make them.

1. Opting for the cheapest surface.

Choosing the cheapest option may seem like a good idea but it often leads to regret later down the track when you’re left having to replace your surface a few years in.

As with many things in life, you get what you pay for. This is the same with playground surfacing. If you want a surface that looks great and lasts a long time, then you might have to pay a little more.

2. Choosing a surface that’s not fit for purpose.

There are many different play surfacing options out there. It’s important to make sure you match the right type of surface to your play area and its specific needs.

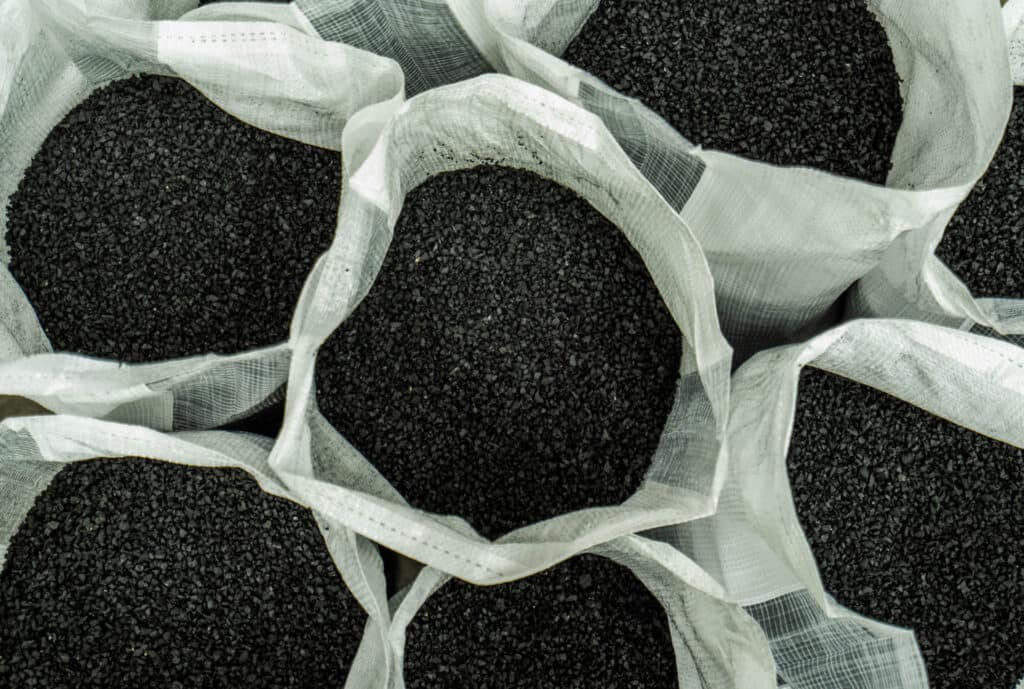

A classic example of where we see this mistake being made is when people put wood chips on a sloped surface.

Wood chips aren’t meant for slopes. They just slide off and create a big mess. You are better off with a one-piece surface that won’t slide, like Pour‘n’Play or MulchSet.

Another common example is when people use bark or wood chips in the under-two’s area of their early childhood centre. We know young children love to put small objects in their mouths. Making wood chip surfacing totally inappropriate for this type of area.

3. Not accounting for equipment height.

The New Zealand Playground Standard outlines the importance of reducing the level of impact in your playground. That means having appropriate surfacing to cushion falls and bumps that might happen under and around play equipment.

A common mistake we see people make here is not installing safety surfacing under their equipment or not adding enough cushioning in their play surface to absorb the shock needed for the height of the equipment in the space.

We often see this in DIY playground installations where people aren’t sure of the playground standard. This is why we recommend always speaking to a safety surfacing professional who can help you choose and install your surface to meet the safety requirements you need.

4. Setting and forgetting.

We’d all love to set and forget when it comes to play surfacing, but unfortunately, it’s not that simple.

Neglecting your surface maintenance can lead to safety issues and decrease the life span of your investment.

We recommend doing regular maintenance checks on your surface.

Remember, wood chip surfaces require weekly checks, annual top-ups, and replacement every 3 years. Wet pour and artificial turf surfaces require less maintenance but should be cleaned and groomed once every 1-2 years.

5. Neglecting surfacing in your budget.

When people think of playgrounds, the first thing that springs to mind is the equipment. Slides, swings, towers, see saws, all of the above. But equipment is only a third of what makes up a good playground.

There’s also design, civil construction, and surfacing among other things, that also have to be included in the budget for a playground. Unfortunately, people often neglect surfacing only to find out later, that they didn’t budget enough to cover the cost of the surfacing they need.

You can avoid this mistake by using our playground budgeting rule of thirds, which you can find here.

6. Missing the opportunity to add extra play value.

This one only really applies to wet-pour rubber surfacing. Wet pour rubber is a highly designable surface. Because of this, you can use it to create surface games and add other meaningful designs to your surface like a logo, unique shapes, and even themes that can tell a story.

We often see people choosing just one overall colour and missing the opportunity to add more play value to their playground through the surface.

Working with a playground surfacing company that can help you get the most out of a great design will leave you with a far more engaging and exciting playground surface.

7. Choosing the wrong colour.

Sometimes aesthetics are important. And when you’re creating an engaging and exciting play environment it can be a significant factor.

Choosing the wrong colour for your playground surface just seems like a missed opportunity. With a surface option like wet pour rubber that offers a wide range of colours and the ability to blend them gives you the freedom and ability to truly personalise your space and showcase your playground’s cultural or imaginative themes.

When selecting your colours, we recommend that you speak to a play surfacing professional who can help you match your colours to the playground’s surroundings, equipment, or culturally significant elements.

8. Not reading the fine print on product warranties.

When it comes to warranties, most of us don’t have the patience to read through the fine print.

But it’s a very important part of the buying process when you are purchasing a play surface. You need to know how long the company’s warranty will last, what is covered, and what isn’t covered.

If you’d like to know more about play surfacing product warranties in New Zealand, check out our warranty video.

9. Not checking your surface provider’s track record.

This is another common mistake we see where people neglect to check the history of the surfacing providers they are considering and their track record here in NZ when they are comparing surfacing options.

We recommend you ask each company you are considering for a list of projects that are five-plus years old that you can visit and check out for yourself. This allows you to see how well the product has lasted.

10. Not considering site access.

When we talk about site access, we are talking about how easy it will be to get materials and equipment in and out of the playground site.

If the site has poor access, then it will be harder to get a truck up to the location for unloading or for machinery like diggers and compactors to get in.

This will impact the overall cost of your playground and should be factored into your budget.

11. Installing new surfacing around an old playground.

Although this might seem like a great way to refresh your playground and knock two birds out with one stone, it’s really doing the opposite.

The problem with installing new surfacing around old playground equipment is that when the old equipment needs replacing you will have to pull up some of the new surfacing with it.

This can be a mess and lead to mismatched surfacing which spoils the look of your surface.

When considering the installation of a new surface it pays to ask whether any of the equipment needs replacing too.